Aluminum Extrusion Profile

Aluminum Extrusion Profiles

Popular Aluminum Products

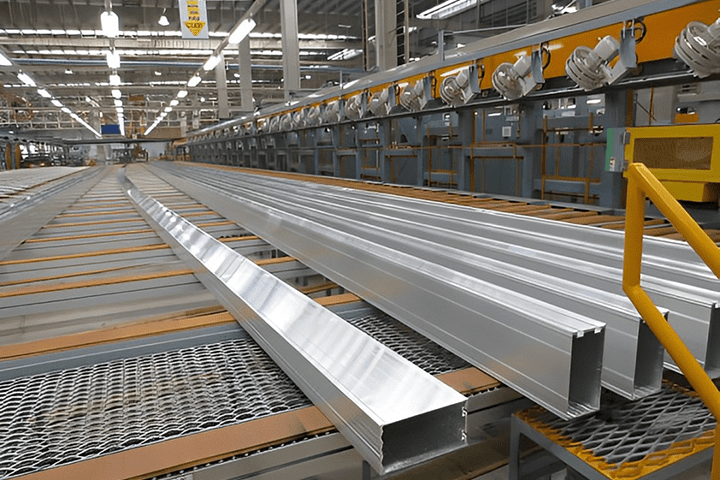

Our extruded aluminum profile offers a diverse range of types, spanning from basic angle pieces to intricately interwoven complex components and tubes, catering to a variety of functional and aesthetic requirements.

Aluminum Extrusion Profile Strengths

Our extruded aluminum profiles are diverse, catering to various needs and applications, with more specific types available for selection.

01.

Rapid Supply

Standard aluminum profiles with a diverse range and ample stock are readily available for prompt supply.

02.

Complete Range

Include aluminum angles, square and round aluminum tubes, T-bars, U-channels, and more.

03.

Customization

We also offer custom aluminum profiles that are meticulously designed to meet our customers' unique design specifications.

04.

Quality Assurance

We promise to offer high-quality aluminum profiles, and in case of any issues, we provide after-sales support to address customer losses.

Applications of Aluminum Extrusion Profile

In various industries, Our aluminum extrusion profile has been widely utilized due to its characteristics of lightweight, corrosion resistance, and good thermal conductivity.

Shipbuilding

Due to the corrosion resistance and lightweight nature of aluminum profiles, they can be used in structural components for shipbuilding, such as hull elements and deck structures.

Automotive

Aluminum extrusions play a crucial role in the automotive industry, especially in essential structural components such as vehicle body frames, engine parts, and suspension systems.

Construction Industry

Due to its lightweight nature, weather resistance, and excellent decorative properties, aluminum profiles are commonly used in building structures, door and window frames, curtain walls, and more.

Medical Equipment

Aluminum extrusions are an ideal choice for manufacturing medical equipment, including wheelchair frames, hospital beds, surgical instruments, and more.

Interior Decoration

Aluminum alloy decorative strips, valued for their lightweight properties and ease of manipulation, are commonly employed in interior decoration and furniture fabrication.

Electronics Industry

Heat sinks made from aluminum extrusions, used in electronic devices and LED fixtures, leverage excellent heat dissipation properties to maintain stable operating temperatures.

Aluminium Alloy Grades and Properties

| Grade | Temper | Overall dimensions /mm | Tensile Strength /MPa | Yield Strength /MPa | Elongation | Tensile Strength/MPa |

| 1070 Aluminum | H112 | ≤120 | 65 | 20 | - | Aluminum foil,capacitor,cable shield,finishing component |

| 2014 Aluminum | T4.T4511 | ≤25 | 380 | 240 | 14 | High strength and elevated hardness (Including High Temperature) situation, such as wheel, truck frame and suspension parts |

| 20-75 | 420 | 280 | 12 | |||

| 75-120 | 400 | 260 | 11 | |||

| 2014A Aluminum | T6.T6511 | ≤25 | 425 | 380 | 7 | |

| 25-75 | 470 | 425 | 8 | |||

| 75-120 | 480 | 430 | 8 | |||

| 2017 Aluminum | T4 | ≤120 | 355 | 255 | 13 | Electric parts of automobile, engine management system |

| 2017A Aluminum | T4.T4511 | ≤25 | 390 | 270 | 13 | Universal machine element, rivets, trafficand building structures |

| 25-75 | 410 | 280 | 11 | |||

| 75-120 | 400 | 270 | 10 | |||

| 2024 Aluminum | T3.T3511 | ≤50 | 460 | 320 | 9 | Truck wheel, airplane structures, and other structures |

| 50-120 | 430 | 290 | - | |||

| 3003 Aluminum | O | ≤120 | 100-140 | 45 | 25 | Demanding high corrosion resistance or good weldability parts, such as energy storage system shield of new energy automobile |

| H11 | 100 | 35 | 25 | |||

| 4032 Aluminum | T6 | ≤120 | 320 | 300 | - | Automotive piston and heat-resistance parts |

| 5052 Aluminum | H112 | ≤120 | 180 | 80 | 15 | Camera casings and other components, transportation vehicles, and ship sheet metal components |

| O | 180-240 | 80 | 18 | |||

| 5083 Aluminum | H112 | ≤120 | 280 | 135 | 13 | ship and automobile weldments |

| O | 280-360 | 120 | 13 | |||

| 6101 Aluminum | T6 | ≤120 | 220 | 180 | 12 | Conductive material, heat dissipation device high-strength rod material for public buses. |

| 6A02 Aluminum | T6 | <120 | 310 | 190 | 13 | Forgings with complicated shapes |

| 6061 Aluminum | T6 | <120 | 280 | 250 | 11 | Automotive shock absorbers, new energyvehicle charging connectors, high-voltagewire connectors, and more. |

| T4 | 200 | 130 | 15 | |||

| 6063 Aluminum | T4 | <120 | 140 | 80 | 15 | Structural components for vehicles, ships. aircraft, and light industrial sectors. |

| T5 | 190 | 140 | 10 | |||

| T6 | 230 | 180 | 12 | |||

| 6463 Aluminum | T4 | <120 | 140 | 80 | 15 | Anodized automotive decorative parts with a bright surface after anodizing. |

| T5 | 170 | 140 | 9 | |||

| T6 | 210 | 180 | 12 | |||

| 6082 Aluminum | T6 | ≤20 | 310 | 260 | 9 | Automotive suspension control arm,Dashboard or instrument panel |

| 20-120 | 330 | 280 | 9 | |||

| 7005 Aluminum | T6 | ≤50 | 370 | 300 | 12 | Vehicle chassis, rods/struts, large-scale heat exchangers, and sports equipment like rackets and baseball bats. |

| 50-120 | 360 | 290 | 12 | |||

| 7020 Aluminum | T6 | ≤50 | 370 | 300 | 12 | Aerospace structural components and automotive welding components. |

| 50-120 | 360 | 295 | 12 | |||

| 7075 Aluminum | - | ≤25 | 550 | 490 | 8 | Aircraft structural-components and other high-stress structural components. |

| 25-120 | 570 | 510 | 8 |